The next generation of binocular inverted metallurgical microscope distributer systems emphasizes automation, safety, and sustainability. Producers are adding AI-fueled monitoring to predict maintenance needs before mechanical issues arise. Improved rotor dynamics minimize vibration and energy consumption, and closed chambers prevent contamination at high speeds. Touch operation and multilingual interfaces simplify ease of use. In processing biological samples or industrial fluids, the new binocular inverted metallurgical microscope distributer unites mechanical robustness with digital intelligence, setting the bar higher for precision, productivity, and durability in industrial and scientific applications.

binocular inverted metallurgical microscope distributer technology is a principal component in diverse manufacturing processes. In wastewater treatment, binocular inverted metallurgical microscope distributer assist in separating sludge from liquids to improve recycling efficiency. In the manufacture of cosmetics, binocular inverted metallurgical microscope distributer facilitate even emulsion and cream mixing. Crop research facilities apply it to analyze soil nutrients and plant extracts. It is also used in the manufacture of vaccines through the purification of viral particles and protein fractions. Through the ability to adapt to many substances and work requirements, binocular inverted metallurgical microscope distributer continues to support industries seeking consistency, purity, and scalability.

The binocular inverted metallurgical microscope distributer technology future lies in automation, digital control, and green engineering integration. Future models will include AI algorithms for speed, balance, and separation efficiency automatic optimization. Energy-efficient motors and recycled materials will reduce environmental impact, following international sustainability goals. Cloud connectivity will allow for remote monitoring and predictive maintenance, with less downtime. In laboratories, binocular inverted metallurgical microscope distributer will be completely compatible with smart data systems for real-time reporting and process validation. These innovations promise greater accuracy, reliability, and versatility for research and industrial use.

Maintenance procedure routines protect the performance and safety of binocular inverted metallurgical microscope distributer. The rotor needs to be visually inspected before each operation for cracks or corrosion. Mild detergents are needed for cleaning, followed by thorough drying to prevent rust. Calibration verification and vibration monitoring assist in keeping it accurate. The instrument should be set on a level surface to reduce stress on bearings. During storage, binocular inverted metallurgical microscope distributer must be kept covered and not plugged to keep electronics safe. Under operator discipline and regular maintenance, laboratories can offer years of trouble-free performance.

binocular inverted metallurgical microscope distributer revolutionized laboratory and industry processes of substance separation forever. By speeding up the sample at high speed, they produce an immense force that separates mixtures based on particle density. This is the mechanism that enables efficient extraction of biological compounds, chemicals, and nanoparticles. Laboratories apply binocular inverted metallurgical microscope distributer for analysis, purification, and research. In industry, they enable the refining of oil and food quality analysis. Small tabletop units and industrial units both use the same fundamental principle—precision with rotational energy and controlled acceleration.

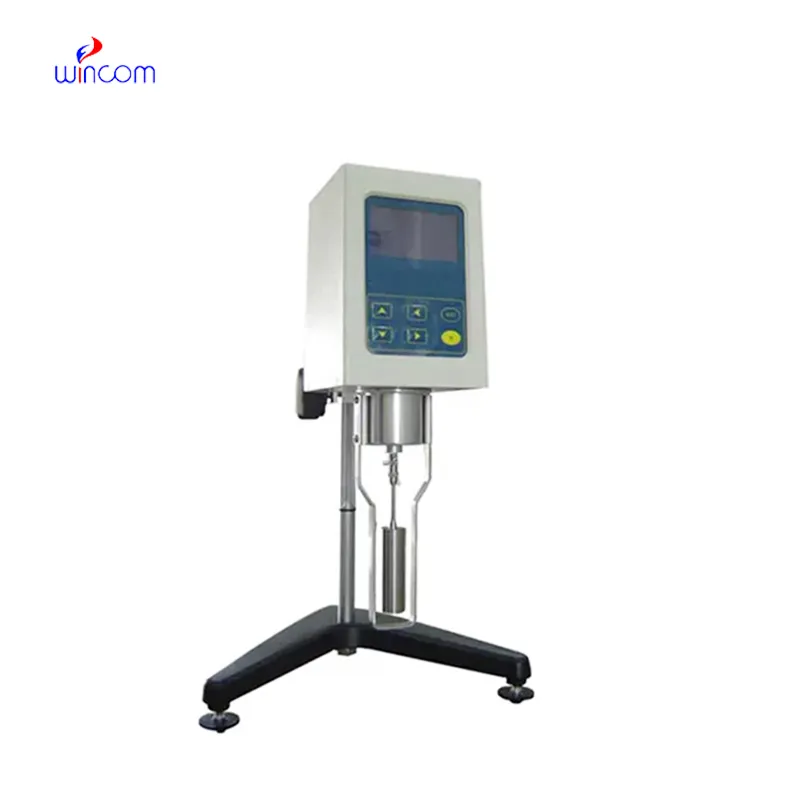

Q: What are the main components of a centrifuge? A: Key components include the rotor, motor, control panel, safety lid, and chamber, each working together to achieve precise separation. Q: How can I verify that a centrifuge is functioning correctly? A: Check that the machine runs smoothly without any unusual vibrations or noises, check the speed accuracy and evaluate the results to ensure consistent separation. Q: Is it safe to open a centrifuge immediately after use? A: No, the device should come to a complete stop before opening to avoid injury or sample disruption. Q: How should a centrifuge be stored when not in use? A:Store it unplugged, covered, and in a dry, dust-free environment to protect internal components from moisture and corrosion. Q: Can centrifuge operation be automated? A: Yes, modern models include programmable controls and digital interfaces that allow automated speed, time, and temperature settings.

This x-ray machine is reliable and easy to operate. Our technicians appreciate how quickly it processes scans, saving valuable time during busy patient hours.

The delivery bed is well-designed and reliable. Our staff finds it simple to operate, and patients feel comfortable using it.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

Hello, I’m interested in your centrifuge models for laboratory use. Could you please send me more ...

We are planning to upgrade our imaging department and would like more information on your mri machin...

E-mail: [email protected]

Tel: +86-731-84176622

+86-731-84136655

Address: Rm.1507,Xinsancheng Plaza. No.58, Renmin Road(E),Changsha,Hunan,China