Recent innovations in uranium centrifuge enrichment technology focus on the improvement of automation as well as information integration. Intelligent models now communicate with laboratory information management systems so that the recording of experimental parameters is no longer problematic. Noise reduction modules and ergonomic covers have also increased user comfort and safety. Also, controlled temperature chambers and high-speed rotors facilitate the handling of sensitive material without degradation. Such technology renders uranium centrifuge enrichment equipment more adaptable to varying research needs, offering unparalled precision in particle separation and purification processes in countless industries.

The versatility of uranium centrifuge enrichment can be seen in its application to numerous specialized fields. In marine biology, it helps one analyze plankton and microbial samples. In food science, it helps with the accurate measurement of fat and protein content. The electronics sector employs uranium centrifuge enrichment for purifying liquid crystals and conductive materials. In environmental protection, uranium centrifuge enrichment facilitate tracking of pollutants and studies on recycling. They aid in veterinary medicine in blood diagnosis and disease investigation. With these uses, uranium centrifuge enrichment bring about innovation through offering dependable means for analyzing as well as separating materials.

{Keywords} in the future will evolve into fully networked instruments in smart laboratories. They will "communicate" with other analytical instruments through built-in digital platforms, making experimental workflows easier. Equipped with self-diagnostic systems, maintenance needs will be identified before any issues arise. Future uranium centrifuge enrichment models will emphasize energy efficiency and portability without compromising on speed or accuracy, while integration with robotics, AI-driven optimization, and user-friendly interfaces will redefine operations standards. In production and research environments, uranium centrifuge enrichment will play a key role in achieving higher productivity and sustainable performance.

Proper care routines prolong the life of uranium centrifuge enrichment significantly. Operators should inspect the rotor for corrosion or scratches after each use and clean with non-abrasive substances. The lid and chamber should be free from residue to prevent contaminations. Frequent lubrication of mechanical interfaces ensures effortless movement. Temperature and humidity control in the storage room protect internal parts against damage. A maintenance record helps track service time and early wear detection. Ongoing maintenance of these factors allows uranium centrifuge enrichment to perform reliably for decades.

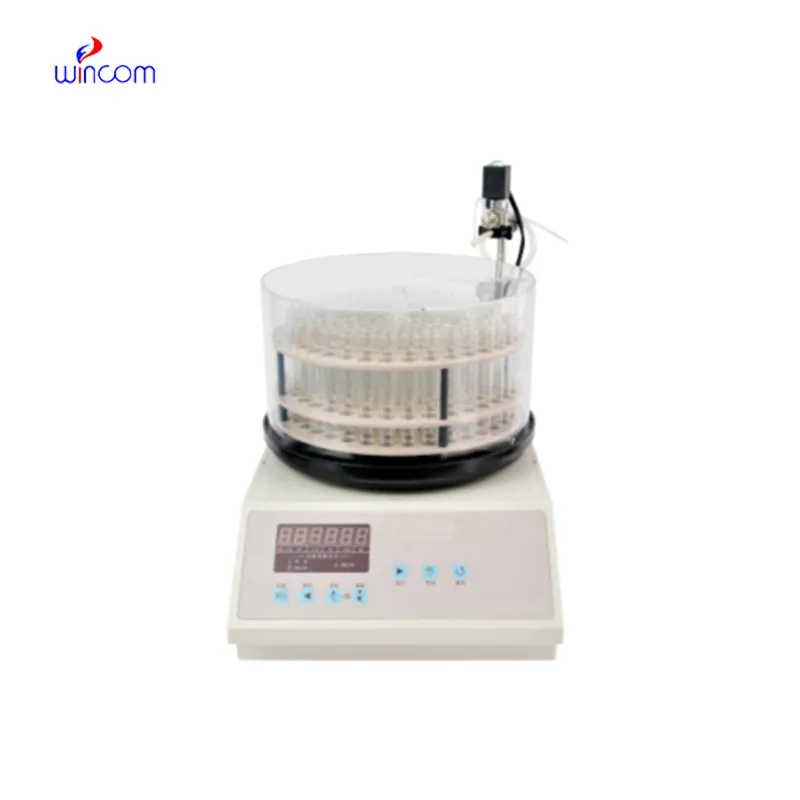

The uranium centrifuge enrichment is a staple equipment in laboratories, industries, and research facilities. Its operation is to isolate particles away from one another based on density and weight by utilizing centrifugal force. Whether examining biological fluids, purifying chemicals, or testing materials, the uranium centrifuge enrichment provides effective separation and purification. Advances in technology have made it faster accurate and automatic, enabling processes to be more repeatable and consistent. From clinical diagnostics to environmental analysis, uranium centrifuge enrichment are essential in furthering precision, productivity, and scientific innovation globally.

Q: What are the main components of a centrifuge? A: Key components include the rotor, motor, control panel, safety lid, and chamber, each working together to achieve precise separation. Q: How can I verify that a centrifuge is functioning correctly? A: Check that the machine runs smoothly without any unusual vibrations or noises, check the speed accuracy and evaluate the results to ensure consistent separation. Q: Is it safe to open a centrifuge immediately after use? A: No, the device should come to a complete stop before opening to avoid injury or sample disruption. Q: How should a centrifuge be stored when not in use? A:Store it unplugged, covered, and in a dry, dust-free environment to protect internal components from moisture and corrosion. Q: Can centrifuge operation be automated? A: Yes, modern models include programmable controls and digital interfaces that allow automated speed, time, and temperature settings.

The centrifuge operates quietly and efficiently. It’s compact but surprisingly powerful, making it perfect for daily lab use.

This ultrasound scanner has truly improved our workflow. The image resolution and portability make it a great addition to our clinic.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

We’re currently sourcing an ultrasound scanner for hospital use. Please send product specification...

Hello, I’m interested in your centrifuge models for laboratory use. Could you please send me more ...

E-mail: [email protected]

Tel: +86-731-84176622

+86-731-84136655

Address: Rm.1507,Xinsancheng Plaza. No.58, Renmin Road(E),Changsha,Hunan,China